Filters

A unique combination of robustness and efficiency allows our high performance filters to purify your compressed air for complete peace of mind. Whichever your required purity, CP filters come in different variants offering a tailored solution for each situation.

Coalescing Filter - G Series

High Efficiency general purpose protection. Filteration 1µm 0.1mg/m; 0.1 mg/m; Residual oil Green identification color. Specifically suitable as pre-filter for dryers by refrigeration as well as for de-oiling device filters, for preventing the tear of piping, of surface treatments, etc…..

The standard coalescing filter uses the Green G element and provides a reliable filter for overall filtration, Excellent low pressure drop More effective than a particulate filter because it also removes lubricant and liquids in suspension Ideal as a pre-filter for removing bulk solids and liquids before

Fine Coalescing Filter - C Series

High Efficiency Oil Removal Filtration. Filtration 0.01µm 0.01 mg/m; Residual oil Red identification color. Specifically suitable as post-filter for dryers by refrigeration, pre-filter for filters series FCA and dryers by adsorption, pneumatic transports, painting plants, control systems, lasers cutting, etc..

The fine coalescing filter uses the Red C element and provides a high level of particulate and coalescing filtration. Maximum coalescing efficiency available. Excellent prevention of oil and fluid carryover into the system. Provides technically oil-free air; exceeds ISO 8573 Class 1 for oil carryover

Carbon activated filter - V Series

Activated Carbon Filtration 0.005 mg/m; Residual oil Silver identification colour. Activated carbon filter to remove steams oil, and hydrocarbons smells. Used in the pharmaceutical, foodstuffs, and chemical industry, photography labs, packaging industry, galvanic treatments, quality

painting, etc.

The adsorbing filter uses the Silver V element and represents the filter that is not able to remove particulates, but is able to remove vapor and odors. Activated carbon media provides sustained protection from harmful vapors and prevents them from moving downstream in the compressed air. Should always be mounted after a C Series or G Series. Used for sensitive applications where the highest air purities are desirable: medical, electronics, pharmaceutical etc.

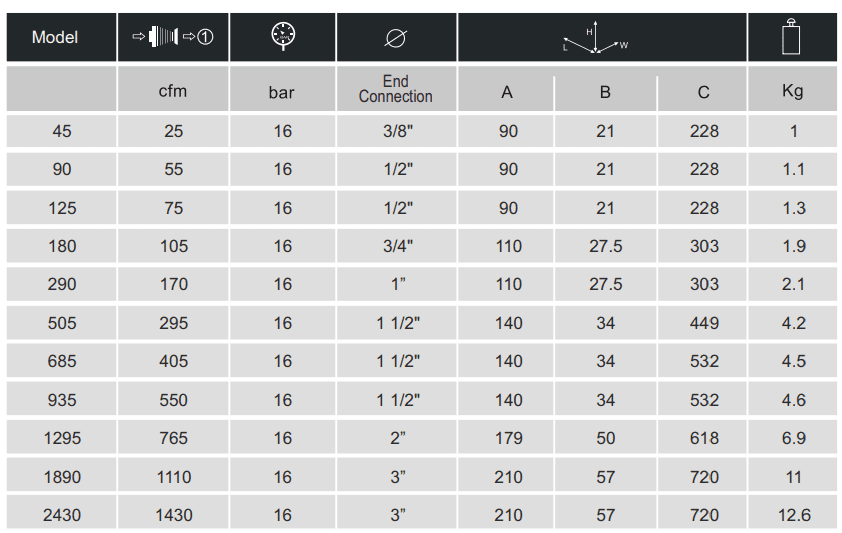

Technical Specifications

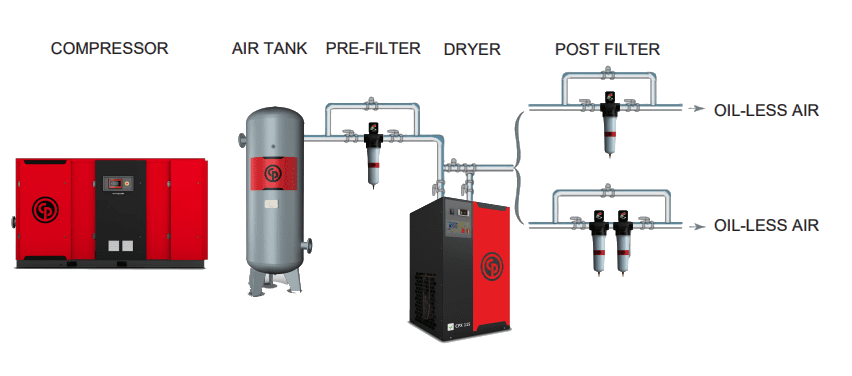

Complete Compressor Room Solutions

Choose innovation, choose our Line Filters for a future-ready solution

Empower your compressed air infrastructure with our Line Filters. Beyond industry standards, they epitomize advanced efficiency and unwavering reliability, ensuring optimal performance for even the most intricate compressed air setups